How to Identify a High-Quality Used Excavator Part: A Buyer’s Checklist (An Insider’s Guide to Inspecting Used Parts Before Purchase and Why Vikfin’s Rigorous Testing Process Ensures High Performance)

- RALPH COPE

- Feb 4

- 4 min read

Updated: Feb 7

Excavators are vital workhorses in industries such as construction, mining, and material handling. But when a crucial part fails, replacing it can be costly. This is where used excavator parts come in, offering a more affordable alternative to new OEM components. However, not all used parts are created equal. A poor-quality part can lead to mechanical failure, downtime, and unexpected costs.

To avoid these pitfalls, this guide provides a thorough buyer’s checklist for identifying high-quality used excavator parts, ensuring longevity, efficiency, and safety in your machine's operation. Additionally, we explore how Vikfin’s rigorous testing process guarantees the highest quality in used excavator parts, giving customers confidence in their purchases.

Why Buy Used Excavator Parts?

Before diving into the checklist, let’s look at why used parts make sense:

1. Cost Savings

High-quality used parts can be significantly cheaper than new OEM parts, sometimes costing 50-70% less.

2. Availability

Certain parts, especially for older excavator models, may be difficult to source new. Used parts keep these machines running.

3. Environmental Benefits

Reusing parts reduces waste and lowers the environmental impact of manufacturing new components.

4. OEM Compatibility

Used parts sourced from original machines retain OEM standards, often outperforming cheap aftermarket alternatives.

However, not every used part is worth the investment. Here’s how to ensure you’re getting a reliable component.

A Buyer’s Checklist for High-Quality Used Excavator Parts

When sourcing used excavator parts, follow this checklist to ensure you’re making a safe and cost-effective decision.

1. Verify the Part Number and Compatibility

Why it matters: Every excavator part is designed for specific models. An incorrect match can lead to improper fitment, inefficiency, and mechanical failure.

How to check:

Cross-reference the part number with the manufacturer’s specifications.

Check if the used part is compatible with multiple models (some brands share parts across different models).

Consult with a knowledgeable supplier like Vikfin, which specializes in sourcing the correct parts.

2. Inspect for Physical Wear and Damage

Why it matters: Excessive wear, cracks, and corrosion can compromise performance and longevity.

How to check:

Examine for cracks, pitting, and rust, particularly in metal components.

Look for excessive wear in moving parts such as hydraulic cylinders and pivot points.

Check the condition of mounting points, as excessive stress fractures indicate a part nearing failure.

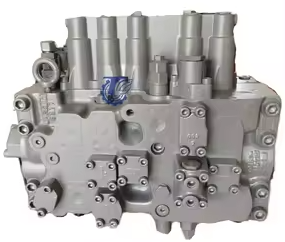

3. Evaluate Hydraulic Components Carefully

Hydraulic parts such as pumps, cylinders, and motors require additional scrutiny.

How to check:

Ensure cylinders have no dents, scratches, or leakage.

Inspect the pump housing for cracks and internal damage.

Test hydraulic motors for smooth operation without grinding noises or excessive resistance.

Ask whether seals and gaskets have been replaced or tested.

4. Check for Signs of Overheating or Excessive Stress

Why it matters: Overheated components can suffer from warping, weakening structural integrity, and potential failure.

How to check:

Look for discoloration, blueing, or burnt marks, especially in engine and transmission parts.

Inspect gear teeth and internal bearings for signs of overheating and unusual wear patterns.

Avoid parts that have been welded, as this may indicate a prior breakage and compromised integrity.

5. Assess the Internal Condition of Major Components

For parts like engines, transmissions, and hydraulic systems, internal condition matters as much as external appearance.

How to check:

If possible, request a compression test for engines to ensure adequate power output.

Examine fluid residue inside transmissions and differentials; burnt or gritty oil indicates internal wear.

Openable components (like gear housings) should be inspected for clean, intact gears and bearings.

6. Request Maintenance and Usage History

Why it matters: A well-maintained part from a properly serviced machine is more reliable than one from a neglected or heavily abused unit.

How to check:

Ask for maintenance logs or service records.

Verify whether the part came from a machine with regular servicing.

Avoid components from machines that operated in extreme conditions (e.g., constant heavy load, underwater excavation).

7. Test the Component If Possible

Why it matters: A working part ensures proper function before purchase.

How to check:

If purchasing locally, request a functional test on site.

For electronic components, verify compatibility with diagnostic tools.

For hydraulic parts, ensure there are no leaks under pressure.

8. Buy from a Reputable Supplier

Why it matters: A reliable supplier ensures proper inspection, guarantees, and fair pricing.

How to check:

Research the supplier’s reputation and reviews.

Choose sellers with a quality assurance program, such as Vikfin.

Avoid private sellers or scrapyards that offer no guarantee.

9. Look for a Warranty or Return Policy

Why it matters: A warranty provides peace of mind and protection against defective parts.

How to check:

Verify if the seller offers a warranty on major components.

Understand the return policy before purchasing.

Why Vikfin’s Rigorous Testing Process Ensures High Performance

At Vikfin, we understand that downtime equals lost revenue. That’s why we follow a strict quality control process to ensure every used excavator part we sell meets the highest standards.

1. Thorough Inspection and Testing

Before any part is added to our inventory, it undergoes:

A visual inspection for structural integrity.

Non-destructive testing for cracks and internal flaws.

Pressure testing for hydraulic parts.

Performance checks for engines and motors.

2. Cleaning and Refurbishment

Parts that meet our criteria are cleaned, repainted if necessary, and refurbished when possible. We replace worn seals, gaskets, and bearings to extend part life.

3. Compatibility Checks

We cross-reference every part to ensure it fits the intended models and functions as expected.

4. Competitive Pricing with a Guarantee

By offering thoroughly tested parts at unbeatable prices, we help customers keep their machines running efficiently without breaking the bank.

5. Expert Customer Support

Our team assists in finding the right part, ensuring that customers get exactly what they need with minimal downtime.

Conclusion: Buy Used, But Buy Smart

Buying used excavator parts can be a game-changer for reducing costs and extending machine life, but only if you purchase high-quality components. By following this buyer’s checklist, you can ensure you get durable and reliable parts that keep your excavator running efficiently.

Vikfin takes the guesswork out of sourcing used excavator parts with a rigorous inspection process, high-quality standards, and unbeatable prices. When you buy from Vikfin, you get more than just a part; you get confidence in its performance and longevity.

Need High-Quality Used Excavator Parts? Contact Vikfin today for expert advice and unbeatable deals on tested, reliable excavator components!

#ExcavatorParts #UsedExcavatorParts #HeavyEquipment #ExcavatorMaintenance #ConstructionEquipment #HydraulicParts #EarthmovingMachinery #ExcavatorRepair #OEMParts #ExcavatorLife #Vikfin #ExcavatorIndustry #ConstructionTools #EquipmentInspection #HeavyMachinery #ExcavatorPerformance #QualityUsedParts #ExcavatorTesting #MachineDowntime #ExcavatorSpareParts

Comments