Fixing and Replacing Excavator Radiators: A Detailed Guide

- RALPH COPE

- Aug 5, 2024

- 6 min read

Updated: Aug 26, 2024

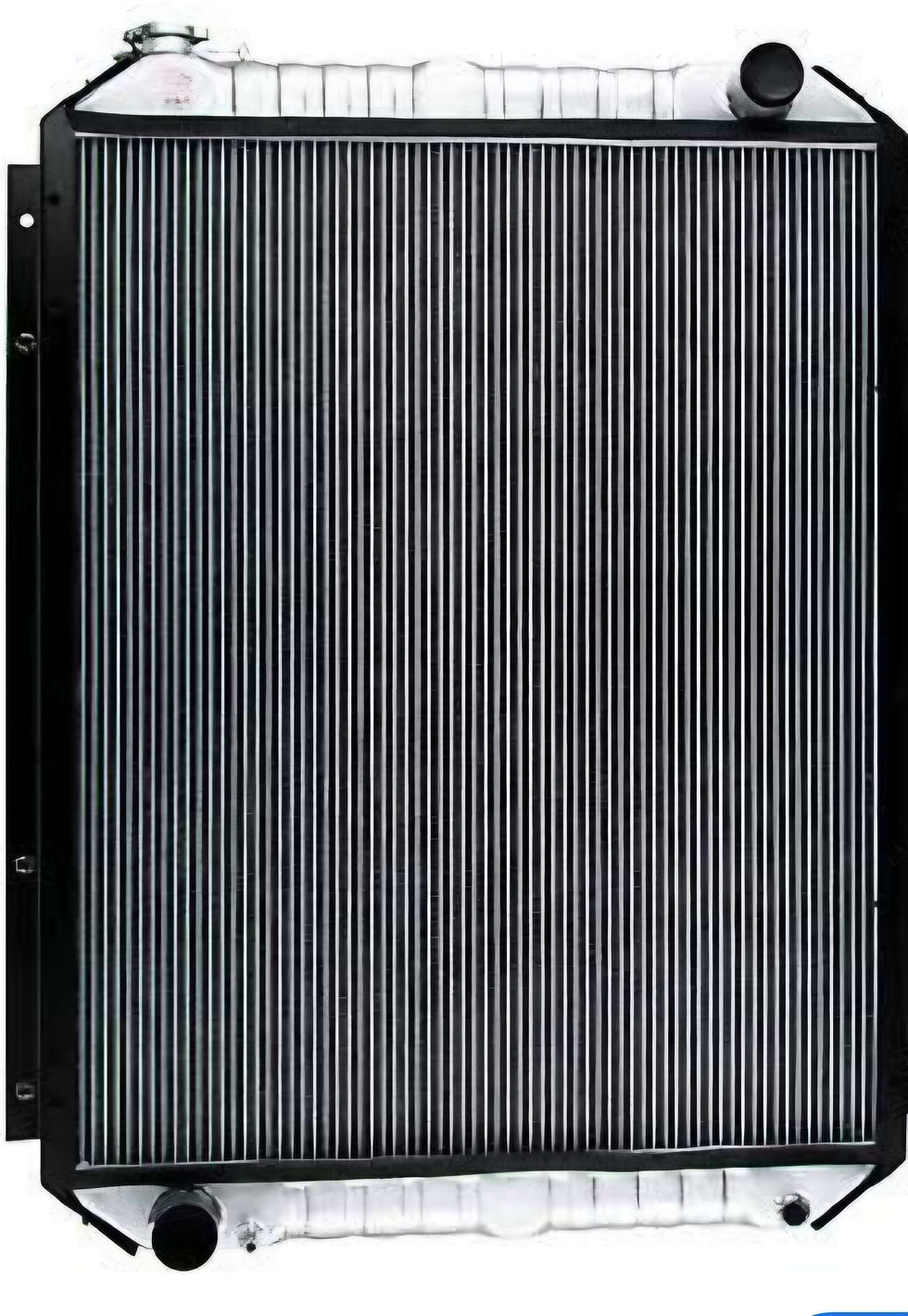

Radiators are vital components in the cooling system of excavators, playing a crucial role in maintaining optimal operating temperatures and ensuring the longevity and efficiency of the machine. However, like all mechanical parts, radiators can suffer damage, with leaks being one of the most common issues. When faced with a leaking radiator, you have two main options: repair it or replace it. This blog will provide a comprehensive guide on how to fix a leaking radiator, and if fixing isn't feasible, why opting for a refurbished radiator from Vikfin is a smart choice.

Identifying a Radiator Leak

Before you can fix a leak, you need to identify its source. Here are some common signs and methods to help you pinpoint a radiator leak:

Visual Inspection: Look for visible signs of coolant leaking from the radiator, such as puddles or wet spots on the ground or on the radiator itself. Often, leaks occur at the joints or seams where the tanks meet the core, or along the core itself if it is damaged.

Coolant Level Check: If the coolant level in the reservoir is consistently low, it may indicate a leak. Refill the coolant and monitor its level over a few days to confirm if there is a drop.

Pressure Test: Using a radiator pressure tester, you can pressurize the cooling system and observe where the coolant is leaking from. This method is highly effective for identifying small, less obvious leaks.

Dye Test: Adding a UV dye to the coolant can help identify leaks with the aid of a UV light. This is especially useful for locating slow or minor leaks that may not be immediately apparent.

Fixing a Radiator Leak

Once you've identified the leak, you can decide on the best course of action to fix it. Here are the steps for repairing a leaking radiator:

Temporary Fixes

Radiator Sealant:

Purchase a Radiator Sealant: Available at most auto parts stores, radiator sealants can provide a temporary fix. They work by circulating through the system and sealing minor leaks.

Follow Instructions: Pour the sealant into the radiator as per the product’s instructions. This typically involves adding the sealant to the radiator or coolant reservoir.

Run the Engine: Allow the engine to run for a specified time to let the sealant circulate and seal the leak. Monitor the coolant level and temperature to ensure the sealant is working effectively.

Epoxy or Silicone Sealant:

Clean the Area: Ensure the area around the leak is clean and dry. Use a wire brush or sandpaper to remove any debris or corrosion.

Apply Sealant: Use a high-temperature epoxy or silicone sealant to cover the leak. Apply a generous amount and spread it evenly over the affected area.

Allow to Cure: Give the sealant adequate time to cure before starting the engine. Follow the manufacturer’s instructions for curing time to ensure a proper seal.

Permanent Fixes

Soldering:

Drain the Radiator: Make sure the radiator is empty and dry before beginning. Disconnect the hoses and drain the coolant into a suitable container for proper disposal.

Clean the Area: Use a wire brush to clean the area around the leak. Removing any dirt, grime, or corrosion is crucial for a successful repair.

Apply Flux: Apply flux to the area to help the solder adhere. Flux is a chemical cleaning agent that improves the bond between the metal and the solder.

Solder the Leak: Use a propane torch and solder to seal the leak. Heat the area until the solder melts and fills the hole. Be careful not to overheat the surrounding areas.

Cool and Test: Allow the solder to cool and then test for leaks by refilling the radiator. Ensure the repair is watertight and that there are no further leaks.

Replacing Damaged Parts:

Remove Radiator: Disconnect the radiator from the excavator, ensuring all hoses and connections are safely removed. This may involve removing the mounting brackets or bolts that secure the radiator.

Inspect and Replace: Identify the damaged section (such as the core or tanks) and replace it with a new or refurbished part. This step may require specialized tools and skills, so consider seeking professional assistance if necessary.

Reassemble: Reassemble the radiator and reconnect it to the excavator. Make sure all connections are secure and that there are no loose parts.

When to Consider Replacement

While fixing a leak can often be a cost-effective solution, there are situations where replacing the radiator might be the better option:

Extensive Damage: If the radiator has multiple leaks, severe corrosion, or significant physical damage, repairs may not be viable. In such cases, replacement ensures the longevity and reliability of the cooling system.

Frequent Leaks: Persistent leaks despite multiple repairs indicate the radiator is nearing the end of its lifespan. Continuous patching can lead to unreliable performance and unexpected failures.

Performance Issues: If the radiator is not efficiently cooling the engine despite being leak-free, it may be time for a replacement. Poor cooling performance can result in overheating, which can cause severe damage to the engine.

Benefits of Choosing a Refurbished Radiator from Vikfin

When replacement becomes necessary, opting for a refurbished radiator from Vikfin offers several advantages:

Cost-Effective: Refurbished radiators are significantly cheaper than brand-new ones, providing a budget-friendly solution without compromising on quality.

Quality Assurance: Vikfin ensures that all refurbished radiators meet OEM standards, guaranteeing reliability and performance. Each radiator undergoes rigorous testing and quality checks before being made available for sale.

Sustainability: Choosing refurbished parts helps reduce waste and supports environmentally-friendly practices. By reusing and refurbishing existing parts, we contribute to a more sustainable future.

Availability: Vikfin stocks a wide range of radiators for various excavator models, ensuring you find the right fit quickly. Our extensive inventory means minimal downtime for your machinery.

Expertise: With specialized staff and years of experience, Vikfin provides exceptional support and guidance in selecting the right radiator for your needs. Our team is always ready to assist you with any questions or concerns.

Steps to Replace a Radiator with a Refurbished One from Vikfin

Order the Right Part: Contact Vikfin with your excavator model and radiator specifications to ensure you get the correct part. Our knowledgeable staff will help you identify the best option for your machine.

Prepare for Replacement:

Safety First: Ensure the engine is cool and disconnect the battery. This step prevents any electrical accidents during the replacement process.

Drain the Coolant: Safely drain the coolant from the radiator and dispose of it according to local regulations. This prevents spills and environmental hazards.

Remove the Old Radiator:

Disconnect Hoses and Connections: Carefully remove all hoses, brackets, and connections attached to the radiator. Labeling these connections can help during reassembly.

Remove Radiator: Take out the old radiator from its housing. This may require assistance if the radiator is large or difficult to access.

Install the Refurbished Radiator:

Position the Radiator: Place the refurbished radiator in the correct position, ensuring it aligns with all mounting points.

Reconnect Hoses and Connections: Reattach all hoses, brackets, and connections securely. Double-check each connection to prevent leaks.

Refill Coolant: Fill the radiator with the appropriate coolant and check for any leaks. Use a coolant that meets the manufacturer’s specifications for your excavator.

Test the System: Start the engine and monitor the temperature to ensure the new radiator is functioning correctly. Check for leaks and make any necessary adjustments.

Conclusion

Dealing with a leaking radiator in your excavator can be a daunting task, but with the right knowledge and tools, it’s manageable. While temporary fixes can buy you time, permanent solutions or replacements are often necessary for long-term reliability. Opting for a refurbished radiator from Vikfin not only saves costs but also guarantees quality and performance, backed by a team of experts dedicated to keeping your machinery running smoothly. Whether you choose to repair or replace, maintaining a healthy radiator is crucial for the optimal performance and longevity of your excavator.

By following this guide, you can make informed decisions about how to handle radiator leaks and ensure your excavator remains in top working condition. Remember, regular maintenance and timely repairs are key to preventing major issues and prolonging the life of your equipment. Choose Vikfin for reliable, cost-effective solutions to all your excavator part needs.

Additional Considerations

Routine Maintenance: Regularly check your radiator and cooling system for signs of wear and tear. Preventative maintenance can help you avoid unexpected breakdowns.

Proper Coolant: Always use the manufacturer-recommended coolant. Using the wrong type can cause damage and reduce the efficiency of the cooling system.

Professional Help: If you’re unsure about repairing or replacing your radiator, seek professional assistance. A qualified technician can provide expert advice and service.

In conclusion, managing radiator leaks effectively requires a combination of timely repairs, routine maintenance, and informed decisions about replacements. With Vikfin’s high-quality refurbished radiators, you can keep your excavator running smoothly without breaking the bank. Our commitment to quality and customer satisfaction ensures you get the best parts and service every time.

#ExcavatorMaintenance #RadiatorRepair #CoolingSystem #HeavyMachinery #ExcavatorParts #RefurbishedRadiator #VikfinQuality #CostEffectiveSolutions #MachineDowntime #RadiatorReplacement #CoolantLeak #HeavyEquipment #OEMStandards #SustainableParts #MachineryCare #PreventativeMaintenance #ExcavatorEfficiency #RepairVsReplace #HeavyDutyRadiators #ExcavatorCooling

Comments