Exploring the Benefits of Used OEM Parts: Quality and Cost Savings Combined

- RALPH COPE

- Nov 28, 2024

- 4 min read

Updated: Nov 30, 2024

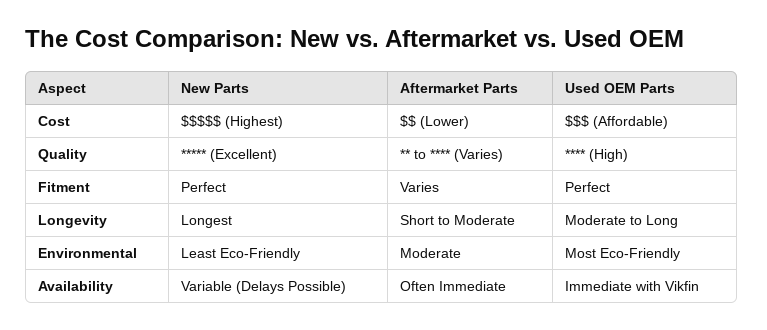

When maintaining or repairing heavy equipment, the decision between new parts, aftermarket alternatives, and used OEM parts can make or break your budget and operational efficiency. Each option offers distinct advantages and disadvantages, but for businesses that prioritize cost-effectiveness without compromising on quality, used OEM parts have become a standout choice. In this blog, we’ll compare these options, dive into the value of used OEM parts, and explain why Vikfin is the ultimate partner for reliable, cost-effective parts.

New Parts: The Fresh Option at a Premium Price

Pros of New Parts:

Pristine Quality: New parts come straight from the manufacturer, ensuring they meet the original specifications.

Warranty: Many new parts come with comprehensive warranties, giving you peace of mind.

Longevity: Fresh components generally promise the longest lifespan under optimal use.

Cons of New Parts:

High Costs: New OEM parts often come with a hefty price tag, particularly for large equipment like excavators.

Availability Delays: Depending on the part, lead times for delivery can stretch into weeks, causing downtime.

Overkill for Older Equipment: Investing in brand-new parts may not always be necessary for older machinery.

When New Parts Make Sense:

New parts are ideal when repairing brand-new machinery still under warranty or for critical components that directly impact safety.

Aftermarket Parts: Affordable but Risky

Pros of Aftermarket Parts:

Lower Prices: Aftermarket parts are typically less expensive than OEM options.

Availability: They’re often more readily available than new OEM parts.

Wide Variety: With numerous manufacturers in the aftermarket space, you have a range of choices.

Cons of Aftermarket Parts:

Inconsistent Quality: While some aftermarket parts are high-quality, others may not meet the same standards.

Fitment Issues: Not all aftermarket parts fit perfectly, leading to operational inefficiencies.

Limited Lifespan: Inferior materials can result in faster wear and tear, increasing the risk of frequent replacements.

When Aftermarket Parts Make Sense:

Aftermarket parts might work for non-essential components where cost savings are the priority over durability or performance.

Used OEM Parts: Quality Meets Affordability

What Are Used OEM Parts?

Used OEM (Original Equipment Manufacturer) parts are components salvaged from machinery that has been retired, refurbished to a high standard, and re-sold. These parts maintain the original manufacturer’s specifications, ensuring they fit perfectly and perform reliably.

Pros of Used OEM Parts:

Cost-Effectiveness: Used OEM parts are significantly cheaper than new ones, providing substantial savings.

Quality Assurance: Unlike aftermarket parts, used OEM parts are built to the same high standards as new OEM components.

Perfect Fit: Because they are genuine parts, they match the original equipment without the guesswork.

Environmental Benefits: Reusing parts reduces waste, making them an eco-friendly choice.

Availability: Reputable suppliers like Vikfin ensure a ready stock of commonly needed components.

Cons of Used OEM Parts:

Variable Condition: The lifespan of a used part depends on its history and refurbishment quality.

Limited Warranties: Warranties on used parts may not be as comprehensive as those on new parts.

When Used OEM Parts Make Sense:

Used OEM parts are ideal for budget-conscious businesses, older machinery, and applications where quick availability is crucial to minimize downtime.

Why Vikfin Is the Best Choice for Used OEM Parts

Vikfin has carved a niche as a reliable supplier of high-quality used OEM parts for heavy equipment. Here’s why they’re a cut above the rest:

1. Extensive Inventory

Vikfin carries a wide range of parts for leading OEMs, including Caterpillar, Komatsu, Volvo, Liebherr, Hitachi, and Doosan. Their vast stock ensures you can find the part you need without extended wait times.

2. Unbeatable Prices

Vikfin guarantees the lowest market prices for used OEM parts, helping businesses stretch their budgets without sacrificing quality.

3. Stringent Quality Control

Every part undergoes rigorous inspection and refurbishment processes to ensure it meets the highest performance standards. This means you get reliability akin to new parts but at a fraction of the cost.

4. Expert Support

Vikfin’s team of specialists offers in-depth knowledge and advice, guiding customers to the right parts for their machinery.

5. Fast Turnaround

With downtime being a critical concern in industries like construction and mining, Vikfin’s efficient logistics ensure prompt delivery, minimizing delays.

Practical Applications of Used OEM Parts

Excavator Repairs: From hydraulic cylinders to slew motors, used OEM parts are a cost-effective solution for maintaining excavators.

Scrap Yard Equipment: Heavy-use machinery in scrapyards often benefits from affordable yet reliable used parts to reduce operational costs.

Plant Hire Businesses: Ensuring a fleet is operational without overspending is crucial in the plant hire industry.

Aging Equipment: Older machinery can stay in service longer with quality parts that match original specifications.

Environmental Impact: Choosing Sustainability

In today’s world, sustainability is a growing priority. Opting for used OEM parts is an eco-conscious choice that contributes to:

Waste Reduction: Preventing functional parts from being scrapped.

Resource Conservation: Avoiding the energy-intensive manufacturing of new parts.

Circular Economy: Supporting the reuse and refurbishment of existing resources.

By choosing Vikfin, you align your operations with environmentally responsible practices.

A Real-World Example: Downtime Avoided with Vikfin

A customer operating a Komatsu PC200 excavator faced unexpected downtime due to a failed final drive. New replacement costs were prohibitive, and aftermarket options risked fitment issues. Vikfin provided a high-quality used OEM final drive at a fraction of the cost and delivered it within 48 hours, saving the customer thousands while getting the machine back to work in record time.

Conclusion: The Smart Choice for Your Business

When comparing new, aftermarket, and used OEM parts, it’s clear that used OEM parts strike the perfect balance between quality and cost savings. For businesses looking to maximize value without compromising reliability, partnering with Vikfin is a no-brainer. Their extensive inventory, expert guidance, and commitment to unbeatable prices make them the go-to supplier for heavy equipment parts.

#HeavyMachinery #ExcavatorParts #UsedOEM #EquipmentMaintenance #CostSavings #Sustainability #Vikfin #MachineryRepair #OEMQuality #ConstructionIndustry #PlantHireSolutions #RefurbishedParts #EarthmovingEquipment #KomatsuParts #VolvoExcavators #LiebherrMachines #HydraulicCylinders #DowntimeSolutions #EcoFriendlyBusiness #AffordableRepairs

留言